-

Fuyong Town, Baoan District, Shenzhen

Essential FAQ on Paper Coatings for Food Packaging Solutions

Revolutionizing Your Brand with Custom Cannabis and Marijuana Packaging Boxes

This article explores the critical role of coating in custom cannabis and marijuana packaging, focusing on how different types of coating impact durability, aesthetics, and overall food packaging safety. We’ll delve into various paper coatings and answer frequently asked questions (FAQ) to help wholesalers, manufacturers, and distributors make informed decisions. This guide is essential reading because it provides practical, actionable insights to enhance your brand image and product appeal, ultimately boosting your market presence.

Table of Contents

1. What are the Main Types of Coatings Used in Cannabis Packaging?

The world of cannabis packaging offers a variety of coating options, each designed to enhance the packaging materials and improve the product’s presentation. The most common types of coating include aqueous coating, UV coating, and varnish. These coatings used provide different levels of shine, from high gloss to a subtle matte finish, and offer various protective qualities. Selecting the suitable coating is a critical component for appealing and practical packaging.

Choosing the right packaging coating enhances both the aesthetic and functional aspects of your paper packaging. Aqueous coating is a popular choice for its eco-friendly nature and fast-drying properties. UV coating, cured with ultraviolet light, offers a high-gloss, durable finish, perfect for creating eye-catching designs. Understanding the differences between these is crucial for creating effective packaging design.

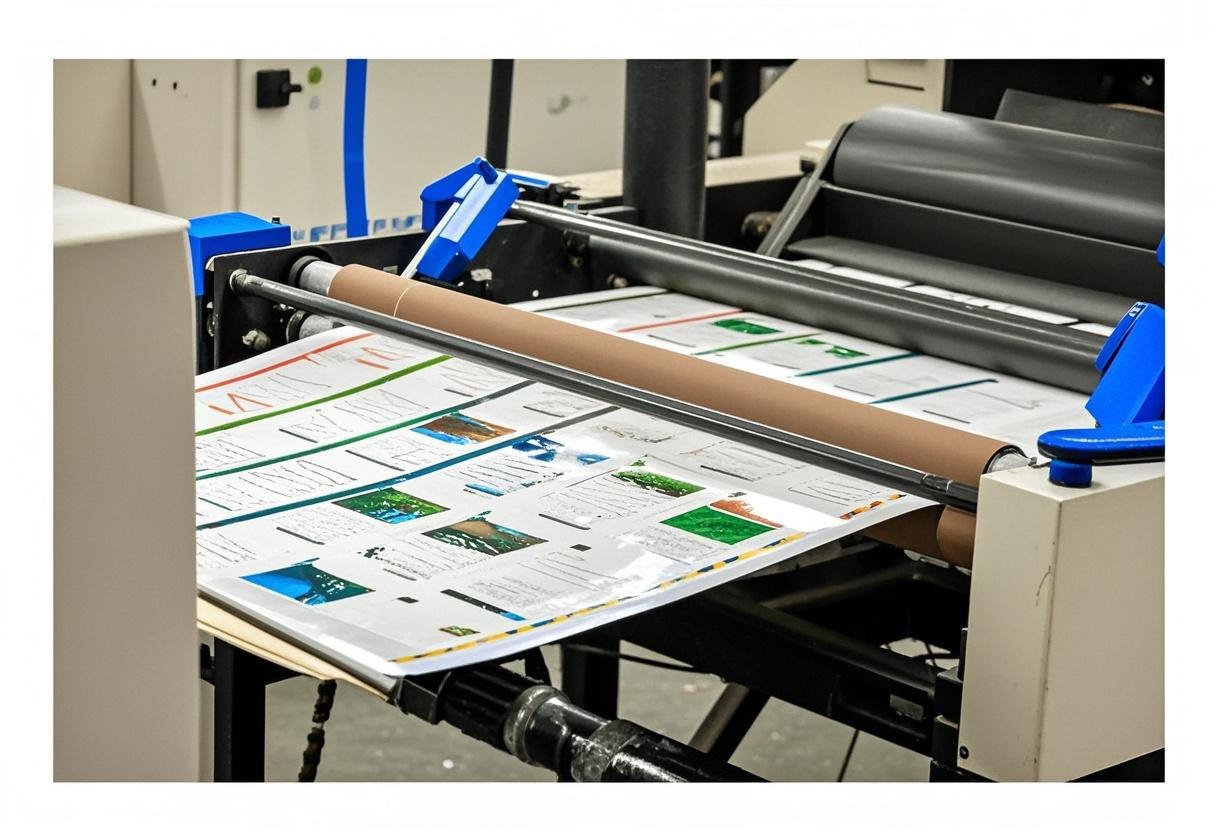

2. Why is Coating Important for Durability and Protection?

Coating plays a vital role in ensuring the durability and protection of cannabis products. Whether it’s flower, concentrates, or edibles, the chosen packaging must protect the product from external elements. A good coating acts as a barrier against moisture, light, and physical damage, preserving the product’s integrity and extending its shelf life. Packaging without adequate protection could expose contents to quality-degrading circumstances.

Furthermore, coating enhances the structural integrity of packaging boxes. For example, a robust coating on a pre-roll box prevents it from crushing, maintaining the perfect condition of the pre-rolls inside. This is particularly important for delicate items like vape cartridges. A protective coating helps ensure that products reach consumers in pristine condition. Check out our Pre-roll Packaging options for optimal protection.

3. How Does Coating Impact the Visual Appeal of Packaging?

Coating significantly influences the visual appeal of printed packaging. A glossy finish can make colors pop and create a vibrant, high-end look, while a matte finish offers a more subdued, sophisticated appearance. The choice between gloss and matte can significantly affect how consumers perceive your brand.

The coating also affects how ink appears on the packaging. Coated paper typically allows for sharper, more vibrant print results compared to uncoated paper. Features like spot UV finishing can highlight specific design elements, like a logo or product name, making them stand out. Elevate your brand’s presence using a well-chosen surface coating. See our Custom Pre-roll Packaging for visually stunning examples.

4. Aqueous Coating vs. UV Coating: Which is Better for Your Cannabis Packaging?

Choosing between aqueous coating and UV coating depends on your specific needs. Aqueous coating is water-based and environmentally friendly, making it a great choice for brands prioritizing sustainability. It provides a smooth surface and is smudge-resistant, though it may offer slightly less gloss than UV. Coating dries quickly, so it helps speed the production process.

UV coating, on the other hand, is cured with ultraviolet light, resulting in a high-gloss, extremely durable finish. It’s excellent for creating a premium look and offers superior protection against scratches and wear. However, it’s less eco-friendly than water-based coating options. The decision hinges on your project’s priorities: sustainability, aesthetics, and durability. Consider the whole packaging requirements before making a decision.

5. What Role Does Coating Play in Food Packaging Safety?

When it comes to edibles, coating is crucial for ensuring food packaging safety. The coating must be compliant with regulations for direct contact with food items. This means it should be non-toxic and not impart any taste or odor to the product. Barrier properties are essential to preserving food quality and preventing contamination.

Coatings used in food packaging must also protect against moisture and other external contaminants, maintaining the freshness and safety of the dry food or edible product. Selecting the type of coating approved for food contact is a non-negotiable aspect of compliance and consumer safety. Our Tincture Packaging is an excellent example of food-safe design.

6. Can Coating Enhance the Tactile Experience of Packaging?

Beyond visuals, coating can also significantly enhance the tactile experiences of your packaging. A soft-touch matte coating, for example, creates a velvety texture that feels luxurious to the touch. This can significantly improve the consumer experience and create a memorable interaction with your product.

Other tactile options include textured varnishes or coatings that mimic the feel of natural materials. Features like emboss or foil stamp techniques, combined with the right coating, can create a multi-sensory experience that elevates your custom product packaging. This customer experience is important for building brand loyalty.

7. How to Choose the Right Coating for Custom Packaging?

Choosing the right coating for your custom packaging involves considering several factors. Think about your brand objectives, the desired aesthetic, and the functional needs of the product. For instance, if you need child-resistant packaging, you might need a specific type of coating that works with locking mechanisms, like we do with our Child Resistant Vape Packaging.

Also, consider your budget. While some coatings, like UV coating, might offer a premium quality appearance, they may also be more expensive. Aqueous coating can be a cost-effective alternative. Evaluate the pros and cons of each type of coating in relation to your packaging performance requirements and budget constraints.

8. What are the Environmental Considerations for Packaging Coatings?

Sustainability is an increasingly important factor in packaging. Paper coatings can impact the recyclability of your paper packaging. Water-based options, like aqueous coating, are generally considered more environmentally friendly than solvent-based or plastic-based alternatives. Consider using options that have a reduced environmental impact.

Some coatings and packaging materials, like certain types of plastic film, can make packaging boxes difficult to recycle. If sustainability is a core value for your brand, look for coatings certified by environmental organizations and communicate your commitment to eco-friendly practices to your customers.

9. How do Printing Techniques Interact with Different Coatings?

The interaction between printing techniques and coatings used is crucial for achieving the desired visual impact. Printed on coated paper, inks generally appear more vibrant and defined. For example, a glossy coating can enhance the richness of colors, while a matte coating can create a softer, more muted effect.

Certain printing techniques, like offset lithography, work exceptionally well with coated paper stocks. It is also important to verify compatibility between ink and coating to ensure the ink will dry properly, without smudging or fading. Some coatings take longer to dry depending on the ink. A proper coating will protect the ink from running, scratching, or experiencing other blemishes. If the printing process needs to disperse inks over the entire surface, certain coatings will not be suitable. A traditional varnish or varnishes may react poorly with certain inks.

10. Frequently Asked Questions (FAQ) about Cannabis Packaging Coatings.

What is the most durable coating for cannabis packaging?

UV coating generally offers the highest level of durability, providing excellent resistance to scratches, scuffs, and moisture.

Is aqueous coating safe for food contact?

Yes, specific aqueous coatings are formulated to be safe for direct food contact, making them suitable for cannabis edibles packaging.

Can I use a matte coating and still have vibrant colors?

While a matte coating will slightly subdue colors compared to a gloss finish, you can still achieve vibrant results, with vibrant, rich color reproduction by using high-quality inks and printing on coated paper.

How does coating affect the cost of my packaging?

Coating adds to the overall cost, but the specific impact varies. Aqueous coating is generally more cost-effective than UV coating.

What type of coating do you recommend for a product in a corrugate box?

Aqueous is a good choice.

Can you have a coating on the outside of the box and not the inside?

Yes, you could have a different coating on the outside and the inside.

Conclusion: Key Takeaways for Cannabis Packaging Coatings

- Coating is crucial for both the aesthetic appeal and functional performance of cannabis packaging.

- Different types of coating, like aqueous and UV, offer varying levels of gloss, durability, and environmental impact.

- Food packaging safety is paramount for edibles, requiring coatings approved for direct food contact.

- Coating can enhance not only the visual but also the tactile experience of packaging.

- Choosing the right coating involves considering factors like brand image, budget, product needs, and environmental responsibility.

- A coating can be an essential element for packaging design.

- Work with experts to get the custom cannabis concentrate packaging box you desire.

- Different coating options work better with different design features.

- Be sure that your ink and coating are compatible.

By carefully considering these factors and working with a knowledgeable packaging supplier like Cannabis Packaging Factory, you can create custom cannabis packaging that protects your product, elevates your brand, and increases consumer appeal, increasing sales. Contact us to learn more and begin working together to create exceptional packaging, including marijuana packaging, designed precisely for your needs.