-

Fuyong Town, Baoan District, Shenzhen

The Ultimate Guide to Foil Stamping: Hot Foil, Cold Foil, and Embossing

Elevate Your Brand with the Ultimate Guide to Foil Stamping: Setting Your Packaging Apart

This article is a comprehensive guide to foil stamping, a premium printing technique that can dramatically enhance your product packaging. We’ll delve into the different types of foil stamping (hot and cold), explore the benefits, and explain how this technique can set your brand apart. As a manufacturer of cannabis packaging boxes and marijuana packaging boxes, catering to wholesalers, manufacturers, and distributors, we understand the crucial role packaging plays in attracting customers and building brand recognition. This article is worth reading because it provides actionable insights into how foil stamping can elevate your packaging, increase perceived value, and ultimately, boost your sales.

Table of Contents

1. What is Foil Stamping and How Does it Work?

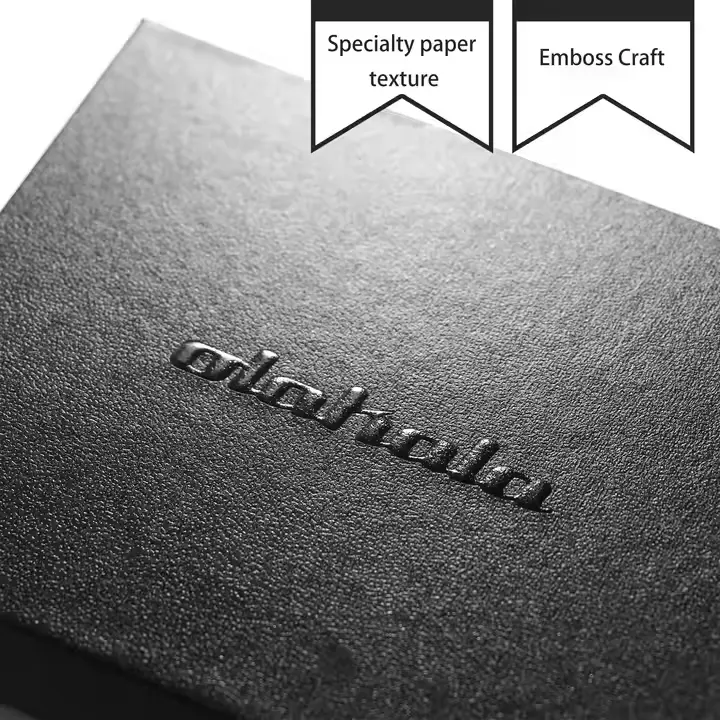

Foil stamping is a specialized printing technique that uses heat, pressure, and metallic foil to create a unique and eye-catching design on various substrates, including paper, cardboard, and plastic. This process, unlike traditional ink printing, results in a luxurious, shiny finish that adds a touch of elegance and sophistication to any product. The foil stamping technique, also known as hot stamping, involves transferring a thin layer of foil onto the material’s surface.

The process involves creating a custom die with the desired design. This die is then heated and pressed onto the foil, causing it to adhere to the substrate in the shape of the design. The result is a stunning, metallic finish that instantly elevates the perceived value of the product. For example, applying gold and silver foil to the product.

2. Hot Foil Stamping vs. Cold Foil: What’s the Difference?

The world of foil application offers two primary methods: hot foil stamping and cold foil. Both achieve a similar metallic effect but differ significantly in their application process and capabilities. Understanding these differences is crucial for choosing the right method for your cannabis packaging needs.

Hot foil stamping, as the name suggests, uses heat and pressure to transfer the foil to the substrate. It is known for its durability, crisp lines, and ability to create intricate designs. It is suitable for a wide range of materials, including paper, cardboard, and even some plastics. Hot foil stamping creates an embossed or debossed effect, making it perfect for adding texture and dimension.

Cold foil, on the other hand, is a newer printing technology that uses a UV-curable adhesive to bond the foil to the substrate. It’s a faster process than hot foil stamping and is generally more cost-effective for large runs. Advantages of cold foil printing include its ability to be applied inline with other printing processes, reducing production time. However, cold foil may not be as durable as hot foil, and it’s typically limited to smooth surfaces.

3. What are the Benefits of Foil Stamping for Packaging?

Foil stamping offers a multitude of benefits for product packaging, particularly in the competitive cannabis market. The benefits of foil stamping go beyond mere aesthetics; they impact brand perception, consumer engagement, and ultimately, sales.

Firstly, foil stamping enhances the visual appeal of packaging. The shiny, metallic finish immediately catches the eye, drawing consumers’ attention on crowded shelves. It creates a sense of luxury and quality, associating your product with premium value. Secondly, foil stamping adds a tactile element to the packaging. The slightly raised or indented texture created by hot stamp provides a sensory experience, further engaging the consumer. This tactile interaction strengthens brand recall and reinforces the perception of a high-quality product. Adding embossing can be particularly effective.

4. How Can Foil Stamping Enhance Brand Identity?

Your brand identity is the essence of your business, and packaging is a crucial touchpoint for communicating that identity to consumers. Foil stamping plays a significant role in reinforcing your brand image and creating a consistent, memorable experience.

Foil can be used to highlight your logo, brand name, or other key design elements, making them instantly recognizable. The use of specific foil colors, such as gold foil or silver foil, can further reinforce your brand’s personality and positioning. For example, gold often conveys luxury and sophistication, while silver suggests modernity and innovation.

Consistency is key to building a strong brand. By incorporating foil stamping across your entire product line, you create a cohesive and professional look that reinforces brand recognition. This consistency builds trust and loyalty among consumers.

5. Foil Stamping Across Industries: Who Uses It?

While foil stamping is widely used in the packaging industry, its application extends far beyond. The versatility of this technique makes it a popular choice for various products and industries.

The luxury goods sector frequently uses foil stamping to enhance the perceived value of their products. From cosmetics and perfumes to high-end spirits and chocolates, foil adds a touch of elegance that aligns with the brand’s premium positioning. Foil stamping is also common in the stationery industry, used on invitations, business cards, and greeting cards to create a sophisticated and memorable impression. Also used by different industries, like: cigarette packaging.

6. The Foil Stamping Process: A Step-by-Step Guide

Understanding the foil stamping process can help you appreciate the craftsmanship involved and ensure optimal results for your cannabis packaging. Here’s a simplified breakdown:

- Design Creation: The process begins with creating the desired design, which will be etched onto a metal die.

- Die Making: A custom die is created, typically from magnesium, copper, or brass, based on the design.

- Foil Selection: The appropriate foil is chosen based on the desired color, finish, and substrate.

- Setup: The die is mounted onto the hot stamping machine, and the foil roll is loaded.

- Stamping: The substrate (e.g., your packaging material) is placed in the machine. The heated die presses the foil onto the substrate, transferring the design.

- Cooling and Finishing: The stamped material is allowed to cool, and any excess foil is removed.

7. Design Considerations for Successful Foil Stamping

While foil stamping offers incredible design possibilities, there are some key considerations to ensure successful foil stamping and achieve the desired impact.

- Font Choice: Fine lines and intricate fonts may not reproduce well with foil stamping. Opt for bolder fonts and simpler designs for optimal clarity.

- Foil Coverage: Large areas of solid foil can sometimes lead to uneven application or “bridging” (where the foil stretches between design elements). Consider using patterns or textures to break up large areas of foil.

- Substrate Compatibility: Not all materials are suitable for foil stamping. Consult with your packaging supplier to ensure your chosen substrate is compatible with the process.

- Color Contrast: Choose foil colors that provide sufficient contrast with the substrate to ensure the design stands out.

8. Is Foil Stamping Right for My Cannabis Packaging?

In the rapidly growing cannabis market, standing out is crucial. Foil stamping can be a powerful tool for differentiating your brand and attracting discerning customers. Cannabis is often perceived as a premium product, and the packaging should reflect that. Foil stamping adds a touch of luxury and sophistication that aligns with the high-quality expectations of cannabis consumers. Consider also: child resistant packaging.

9. What are the Different Types of Foil Available?

The world of foil extends far beyond just gold and silver. A wide range of colors, finishes, and special effects are available to create truly unique and eye-catching packaging.

- Metallic Foils: These are the most common type, offering a classic shiny finish in various colors, including gold, silver, copper, bronze, and more.

- Pigment Foils: These foils provide a matte or glossy finish in a wide range of colors, without the metallic sheen.

- Holographic Foils: Holographic foils create a stunning rainbow effect that changes with the viewing angle, adding a dynamic and modern touch.

- Specialty Foils: This category includes a variety of unique foils, such as pearl, brushed, and textured foils, offering endless design possibilities.

10. How to Make a Lasting Impression with Foil Stamping?

Foil stamping, when executed thoughtfully, can elevate your cannabis packaging from ordinary to extraordinary, creating a lasting impression on consumers.

- Focus on Key Elements: Use foil to highlight your logo, brand name, or other crucial design elements, drawing the eye and reinforcing brand recognition.

- Create a Sensory Experience: Combine foil stamping with embossing or debossing to add a tactile element that engages multiple senses.

- Tell a Story: Use foil to subtly communicate your brand’s values and story. For example, a delicate foil pattern could represent the intricate details of your cultivation process.

- Use custom pre roll packaging.

FAQs:

What is the difference between hot foil stamping and cold foil stamping?

Hot foil stamping uses heat and pressure to transfer the foil, while cold foil uses a UV-curable adhesive. Hot foil is generally more durable and allows for embossing, while cold foil is faster and more cost-effective for large runs.

Can foil stamping be used on any type of packaging material?

Not all materials are suitable for foil stamping. It’s essential to consult with your packaging supplier to ensure compatibility. Paper, cardboard, and some plastics are generally compatible.

How much does foil stamping cost?

The cost of foil stamping varies depending on factors such as the size of the design, the type of foil, the quantity, and the complexity of the process. It’s best to get a custom quote from your packaging supplier.

What is the turnaround time for foil stamping?

The turnaround time can vary depending on the complexity of the project and the supplier’s workload. Typically, it takes longer than standard printing, so factor that into your production schedule.

Does foil stamping make it hard to recycle the packaging?

Foil is a very small addition of material to a package and does not hinder the recyclability of the base material.

Can I use multiple foil colors in one design?

Yes, multi-color, or multi-pass is possible. However, it requires multiple stamping and can add to the overall cost and production time.

Key Takeaways:

- Foil stamping is a premium printing technique that adds a touch of luxury and sophistication to packaging.

- Hot foil stamping uses heat and pressure, while cold foil uses a UV-curable adhesive.

- Foil stamping enhances visual appeal, brand identity, and perceived value.

- A wide range of foil colors, finishes, and special effects are available.

- Careful design considerations are crucial for successful foil stamping.

- Foil stamping can be a powerful tool for differentiating your cannabis brand.

- Foil can be used with other printing technologies.

- Foil can be used to highlight security features, such as holograms on your product.

We are committed to providing high-quality cannabis packaging solutions that help your brand succeed. If you’re interested in learning more about how foil stamping can elevate your packaging, contact our packaging experts today for a free consultation and receive a no-obligation price estimate. Let us help you make your brand unforgettable with stunning foil-stamped packaging!