-

Fuyong Town, Baoan District, Shenzhen

What products require child resistant packaging

Child-Resistant Packaging: Ensuring Safety for Household Products and Beyond

This article provides a comprehensive overview of child-resistant packaging (CRP), explaining its importance, the regulations that govern it, and the various types available. It’s crucial reading for wholesalers, manufacturers, and distributors in the cannabis and related industries, as understanding these requirements is essential for compliance and ensuring the safety of consumers, especially children. As manufacturers of cannabis packaging boxes and marijuana packaging boxes, we are dedicated to providing our clients with detailed information and compliant solutions, making this a must-read guide.

Table of Contents

1. What is Child-Resistant Packaging (CRP) and Why Is It Important?

Child-resistant packaging (CRP) is designed to be significantly difficult for children under five years of age to open or obtain a toxic or harmful amount of the substance contained therein within a reasonable time. It’s not about making the packaging impossible for children to open, but rather to delay access long enough for an adult to intervene. This delay is critical in preventing accidental ingestion of hazardous household products, pharmaceuticals, and, increasingly, cannabis products.

The importance of CRP cannot be overstated. Accidental ingestion of hazardous substances is a leading cause of injury and even death among young children. Effective CRP significantly reduces this risk, protecting children and providing peace of mind to parents and caregivers. For businesses, using CRP is not just a legal requirement for certain products; it’s a demonstration of commitment to consumer safety and responsible business practices.

2. What is the Poison Prevention Packaging Act (PPPA), and How Does It Affect My Business?

The Poison Prevention Packaging Act (PPPA) of 1970 is a US law that empowers the Consumer Product Safety Commission (CPSC) to establish standards for child-resistant packaging of household substances. The PPPA aims to protect children from serious personal injury or serious illness resulting from handling, using, or ingesting such substances.

For businesses involved in manufacturing, wholesaling, or distributing products that fall under the PPPA, compliance is mandatory. This means ensuring that your packaging meets the specific test requirements outlined in 16 CFR Part 1700. Failure to comply can result in significant penalties, including fines and product recalls. As a manufacturer, understanding the PPPA is crucial in choosing suitable marijuana packaging boxes or cannabis packaging boxes that fulfill all safety stipulations. The act covers a range, and being informed is the first step.

3. What Products Require Child-Resistant Packaging?

A wide range of products require child-resistant packaging. These include, but are not limited to:

- Household cleaning products: Bleach, detergents, furniture polish.

- Pesticide products: Insecticides, herbicides, rodenticides.

- Pharmaceuticals: Prescription and over-the-counter medications.

- Dietary supplements: Particularly those containing iron.

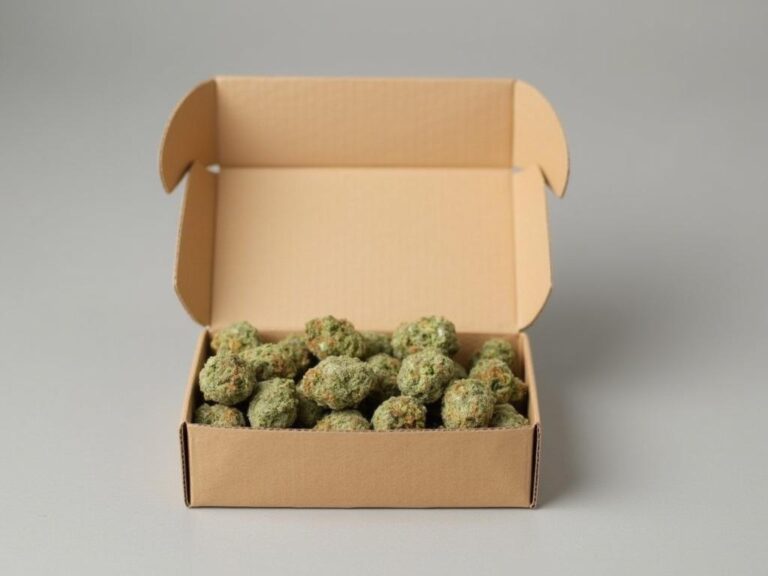

- Cannabis Products: Edibles, concentrates, vape cartridges.

- Mouthwash.

- Liquid nicotine.

The EPA and the CPSC maintain lists of substances that require CRP. It’s essential for businesses to stay informed about these lists and any updates to them. If you’re unsure whether your product requires CRP, it’s best to err on the side of caution and consult with packaging experts. The determination depends on the product and its ingredients.

4. What are the Specific EPA and CPSC Requirements for Child-Resistant Packaging?

The EPA and the CPSC have specific, and sometimes differing, requirements for child-resistant packaging. The CPSC, under the authority of the PPPA, focuses on household substances, while the EPA regulates pesticide products. Both agencies, however, generally follow standards developed by ASTM International (formerly known as the American Society for Testing and Materials).

The test requirements typically involve testing the packaging with groups of 50 children aged 42-51 months. The package must be difficult for children to open, but easy for adults to use. Specific criteria, such as the percentage of children unable to open the package within a given time, are outlined in 16 CFR Part 1700 and 40 CFR 157.32. US EPA also provides detailed guidelines. CRP must resist children but also be usable by seniors.

Specifically for pesticide products, 40 CFR 157.32 including the revised standards details the necessary child-resistant effectiveness and senior use effectiveness levels. It’s vital to use these standards as your benchmark.

5. What are the Different Types of Child-Resistant Packaging Available?

There are many types of child-resistant packaging options, each with its own advantages and disadvantages. Some common examples include:

- Blister packs: Individual doses are sealed in separate compartments, requiring multiple steps to access.

- Reclosable containers: These utilize mechanisms such as squeeze-and-turn caps, push-and-turn caps, or locking mechanisms that require dexterity and strength that young children typically lack.

- Pouches

- Unit dose packaging: Each dose is individually packaged, limiting the amount a child could access at one time.

The choice of package type depends on the specific product, its form (liquid, solid, powder), and the target user. For example, vape cartridge packaging requires a different approach than packaging for edibles. Some solutions can be considered, such as child-resistant 5-pack pre-roll packaging.

6. How is Child-Resistant Packaging Tested to Ensure Effectiveness?

Child-resistant packaging undergoes rigorous testing to ensure its effectiveness. The testing procedures in 16 CFR Part 1700 detail the protocol, which typically involves:

- Child Testing: Groups of 50 children aged 42-51 months are given the package and allowed to try to open it for a specified time (usually 5 minutes).

- Adult Testing: A separate group of adults, including seniors, is tested to ensure that the packaging is not difficult for normal adults to use properly.

The package passes the test if a specified percentage of children (usually 80% or 85% depending the time allowed, 5 or 10 minutes) cannot open it, while a high percentage of adults (usually 90%) can open and properly reclose it. Testing needs to be handled by an independent lab.

7. What are the Requirements for Pharmaceutical Packaging?

Pharmaceutical packaging has particularly stringent packaging requirements due to the potential dangers of medication ingestion. In addition to the general requirements of the PPPA, pharmaceutical packaging must often meet additional standards related to factors such as:

- Moisture and light protection: To maintain the stability and efficacy of the medication.

- Tamper evidence: To indicate if the package has been opened or compromised.

- Unit-dose packaging: Used for precise dose.

These additional requirements aim to ensure the safety and integrity of the medication from the manufacturing facility to the patient’s hands. These include factors, child-resistant closures, and child resistant blisters.

8. How Do I Certify That My Packaging Meets CRP Standards?

To certify that the packaging used for your product meets CRP standards, you typically need to:

- Select appropriate child-resistant packaging: Choose a packaging design that is known to meet CRP standards, or work with a packaging supplier to develop a custom solution.

- Conduct testing: Have the packaging tested by a qualified third-party laboratory according to the relevant protocols (e.g., 16 CFR Part 1700, ASTM D3475).

- Obtain certification: The testing laboratory will provide a report and certification if the packaging passes the tests.

- Maintain records: Keep detailed records of the testing and certification, as these may be required by regulatory agencies.

It’s important to note that certification is not a one-time event. Ongoing quality control and periodic retesting may be necessary to ensure continued compliance.

9. What are the Common Challenges in Designing and Implementing CRP?

Designing and implementing CRP can present several challenges:

- Balancing child resistance with adult usability: It’s crucial to find a design that is difficult for children to open but still easy for adults, especially seniors or those with dexterity limitations, to use.

- Cost: CRP can be more expensive than non-CRP, impacting the overall product cost.

- Aesthetics: Some CRP designs may be perceived as less attractive or less convenient than non-CRP options.

- Material compatibility: The packaging materials must be compatible with the product and not degrade or react with it.

- Staying Up to Date: It’s important to stay informed, Cannabis Pre Roll Packaging Wholesale will make it simpler.

Addressing these challenges requires careful planning, collaboration with packaging experts, and a commitment to continuous improvement.

10. What’s the Future of Child-Resistant Packaging? Innovations and Trends

The field of child-resistant packaging is constantly evolving, with ongoing innovations and trends aimed at improving safety, usability, and sustainability. Some key areas to watch include:

- Smart packaging: Incorporating sensors or other technologies to monitor package access or provide reminders to reclose the package.

- Biometric packaging: Using fingerprint or other biometric recognition to control access to the package.

- Sustainable materials: Developing CRP from eco-friendly materials, such as bio-based plastics or compostable materials.

- Improved usability: Designing CRP that is easier for adults to open and close, while still maintaining child resistance.

- Universal Design: Designing CRP to be usable by as wide range range of users as possible.

These innovations hold the promise of even more effective and user-friendly CRP in the future. For example, innovations such as custom pre-roll packaging are consistently being developed.

FAQs

What is the main purpose of child-resistant packaging?

The main purpose is to prevent children under five from accessing potentially harmful substances.

Are all household products required to have child-resistant packaging?

No, only those containing hazardous substances as defined by the CPSC and EPA.

How can I tell if a package is child-resistant?

Look for labeling that indicates it meets CRP standards, or consult with the manufacturer or supplier. Check for directions on how to use them.

Can adults with disabilities use child-resistant packaging?

Yes, CRP is designed to be difficult for children, not impossible for adults, including those with disabilities. Testing is also designed for seniors.

Where can I find more information about CRP regulations?

The CPSC and EPA websites provide detailed information about CRP regulations and testing protocols.

Is child-proof packaging the same as child-resistant packaging?

“Child-proof” is often used informally, but “child-resistant” is the correct technical term. No packaging is entirely child-proof.

Key Takeaways:

- Child-resistant packaging (CRP) is essential for protecting children from accidental ingestion of hazardous substances.

- The Poison Prevention Packaging Act (PPPA) mandates CRP for certain household products.

- The EPA and CPSC have specific requirements for CRP, outlined in 16 CFR Part 1700 and 40 CFR 157.32.

- There are various types of CRP available, including blister packs, reclosable containers, and unit dose packaging.

- CRP undergoes rigorous testing to ensure its effectiveness.

- Pharmaceutical packaging has additional requirements beyond the PPPA.

- Businesses must certify that their packaging meets CRP standards.

- Designing and implementing CRP presents challenges, such as balancing child resistance with adult usability.

- The future of CRP includes innovations like smart packaging, biometric packaging, and sustainable materials.

- Custom Tincture Packaging is another area of focus.

- Designing packaging, that includes custom-cigarette-packaging-boxes/, includes several factors.

By understanding and adhering to CRP regulations, businesses can play a vital role in protecting children and promoting consumer safety. As a manufacturer of cannabis packaging box and marijuana packaging box products, we are committed to providing compliant and effective packaging solutions for our customers.